Jiangsu Xinlingyang Technology Co., Ltd. was founded in 2002, with a registered capital of 20 million yuan, initiated by the former Jiangsu Lingyang Cement Engineering Technology Co., LTD.We are a high-tech enterprise, specializing in new material technology research and development, industrial engineering design and services, engineering management, grinding technology and equipment for cement/slag/steel slag and other solid waste, industrial electrical and automation control system integration, cement plant production system

transformation, commissioning and other services.

We are committed to providing systematic and whole-process services for the owners and have a good market reputation in the fields of cement and slag powder at home and abroad.We have undertaken and completed engineering design, EPC, equipment supply and

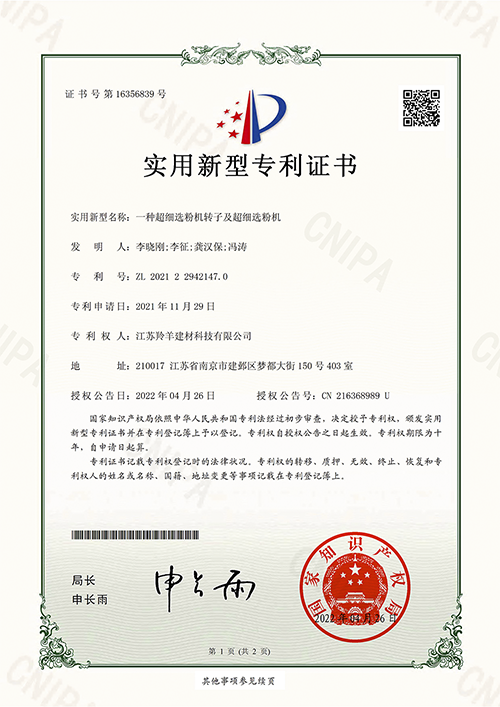

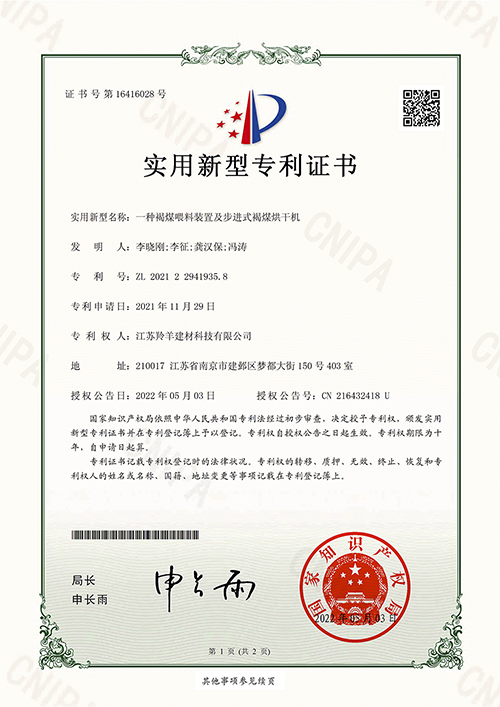

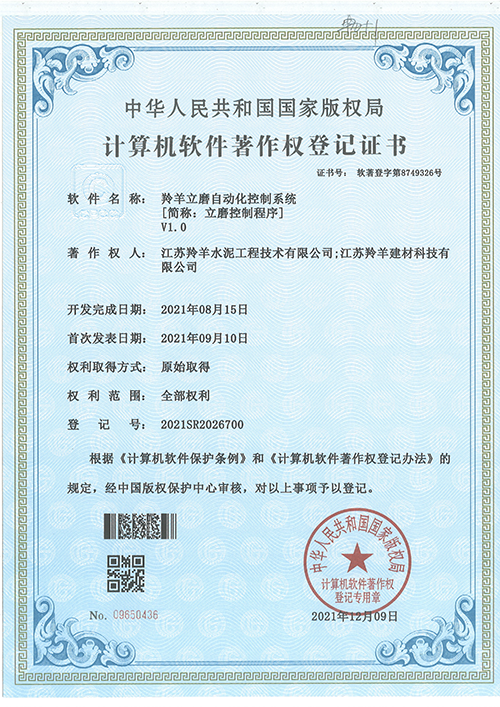

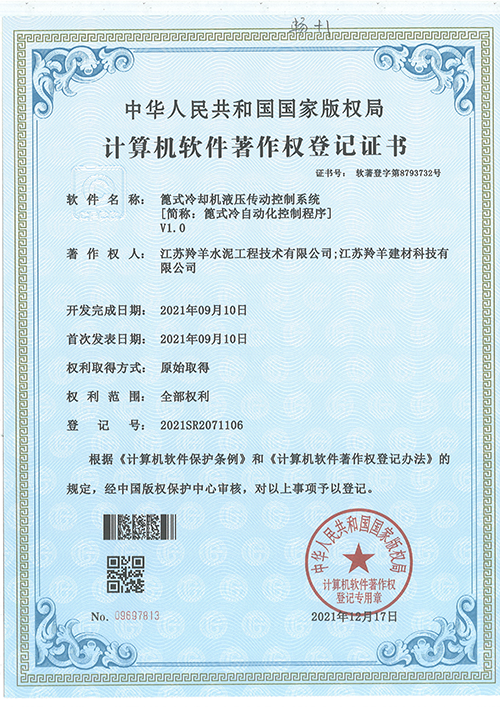

other technical services for 70 production lines of cement and slag, also have completed technical transformation projects for more than 50 cement production lines of preheater, grate cooler, raw material grinding and so on.We have a number of national patents. In the

industry, we have our own unique technical advantages, advanced products and equipments, a group of senior and experienced engineers and technical personnel.

We have a large equipment manufacturing plant in Changzhou Liyang City, Jiangsu Province, covering an area of 60000 square meters, building area of 30000 square meters, 100 sets of various large and medium-sized mechanical processing equipment. It can produce

vertical mill, preheater, grate cooler (third generation, fourth generation, fifth generation), burner, efficient dynamic separator, roll crusher, and other industry-specific equipment, which have been successfully applied to more than 80 cement production lines at home and

abroad and widely praised by owners. Jiangsu Xinlingyang has reached the domestic advanced level in cement/slag vertical grinding processing, manufacturing and engineering area.We cooperate with LOESCHE, FLSIMIDTH,THYSSENKRUPP and other international

enterprises to produce related supporting equipment.

In the field of cement industry automation control, we have carried out extensive cooperation with international well-known control system suppliers such as Schneider, ABB, SIEMENS, AB, etc., to provide high quality products and satisfactory service for cement enterprises.

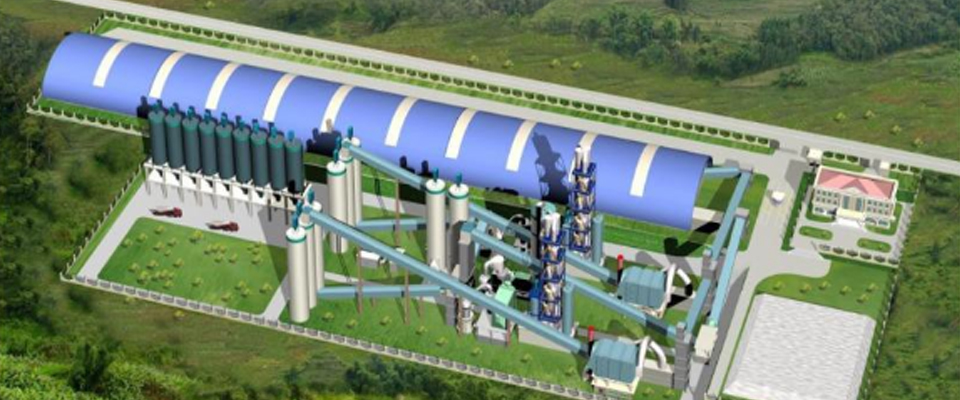

In Qingyang, Anhui, we have built a cement grinding production demonstration line.By independent research and development, we adopt a "vertical mill + ball mill" mixed cement grinding production process to achieve the substantial improvement in cement production

quality and the reduction in energy consumption, especially suitable for the transformation of existing cement grinding production lines.The "multi-sorting high-efficiency cement vertical mill" developed by our company has reached the advanced level of the domestic, and has been identified as a high-tech product by the Science and Technology Department of Jiangsu Province.

In 2017, we introduced brown coal treatment technology from Germany, and combined with our technical advantages in the cement industry for many years, and established Mile Lingyang Clean Energy Co., Ltd. in Mile, Yunnan to improve the quality of brown coal with

high moisture and low calorific value from coal mining into clean coal with low moisture and high calorific value. At present, the annual output is 1 million tons, and the products are used in cement, chemical metallurgy, power plants and other fields.The use and added

value of the products are greatly improved.

Since 2018, we have carried out in-depth research on new materials such as steel slag and solid waste, and have built a solid waste treatment production line of "rod mill + iron removal + vertical mill" in Qingyang test base. The solid wastes such as steel slag and

phosphorus slag are deeply processed by means of physical grinding and chemical excitation to stimulate their activity and be used as admixtures for building materials. And have achieved good social benefits and economic benefits.

We will give full play to our own advantages under the development concept of "do professionally,do fine, do excellently", and is committed to building a high-tech enterprise that integrates design, research and development, manufacturing and service, and has

independent intellectual property rights and core competitiveness.We will enhance the competitiveness of enterprises through continuous technological innovation.