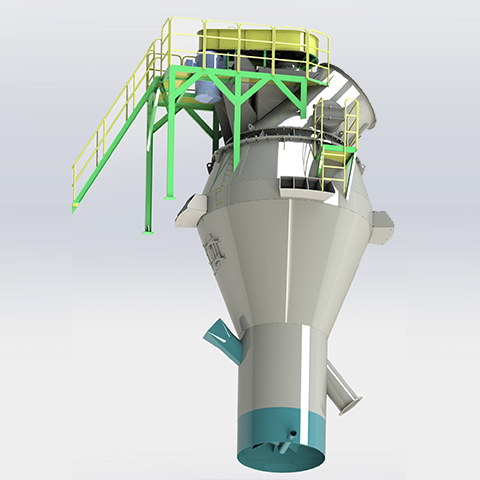

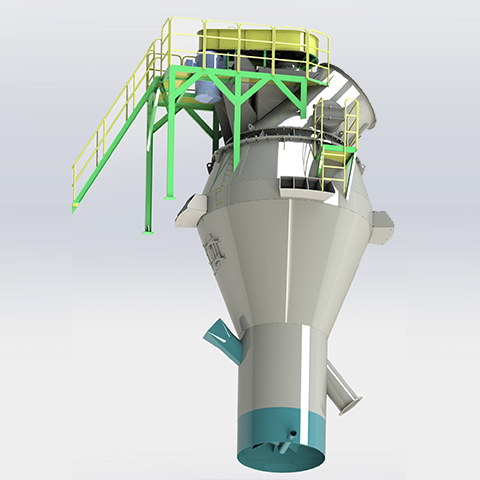

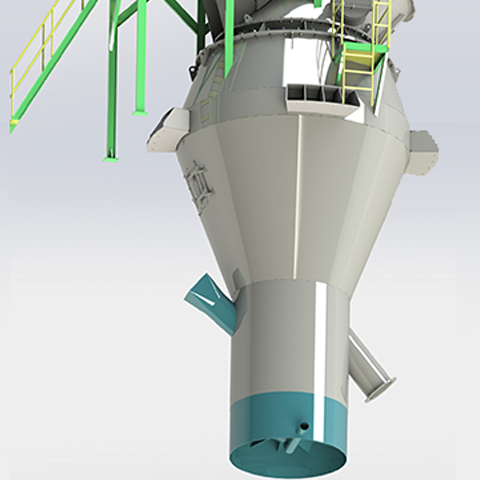

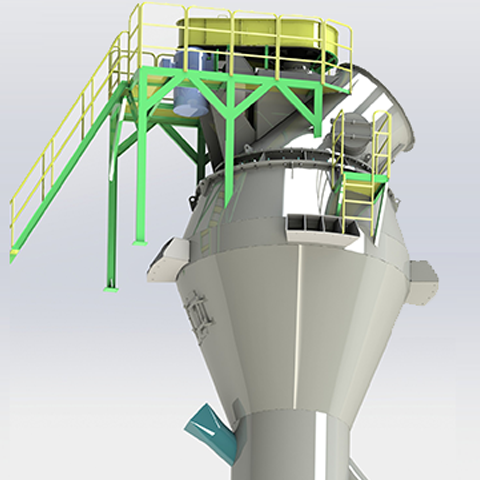

Cement Mill Separator

Introduction:

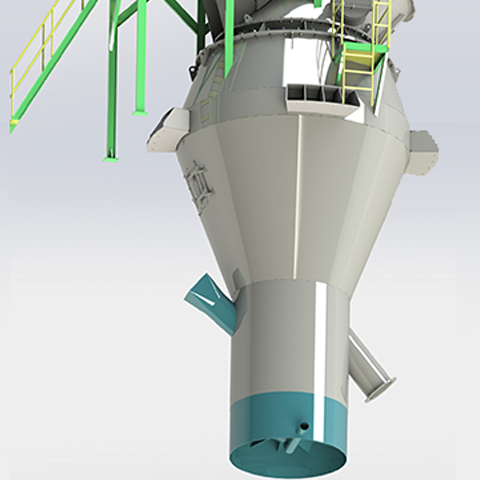

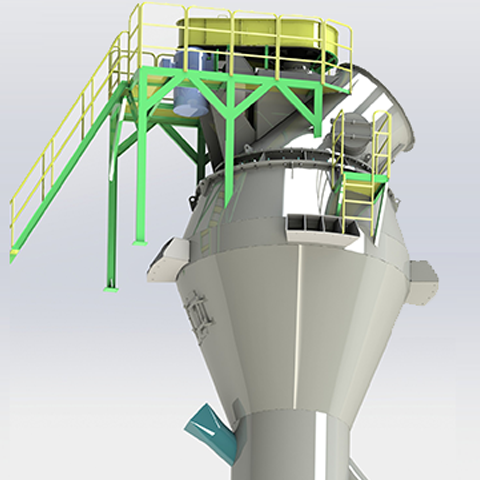

Cement mill separator use fluidization device to fully mix the material and air flow. After blowing through the diversion device, the inlet air is mixed with the material to form a spiraling air-material mixture. The rotation direction of the air-material mixture is basically the same as the angle of the guide blade, which effectively reduces the wear of the guide blade. The special shape of the air chamber can effectively prevent the coarse material from constantly rotating and staying between the rotor and the static blade, so that the fine material entering the sorting area can be effectively sucked into the rising channel, avoiding the mixing of the sorted and unsorted materials, so that there is no fine in the coarse and no coarse in the fine.

The separator is widely used in building materials industry,metallurgy industry, power generation, chemical industry,and has applied for a number of national patents:

ZL 2015 1 0447740.4 A high-efficiency rotary separator;

ZL 2019 2 0078462.3 A vertical ultra-fine separator;

ZL 2021 2 2348720.5

ZL 2021 2 2942147.0

Can be applied to the various material properties of different industries

(1)The inlet air and material are mixed evenly to avoid the phenomenon of material clumping.

(2)The air-material mixture is spirally raised, which increases the lifting force of the air and reduces the differential pressure of the powder separator.

(3)The powder separator adopts frequency control, speed control is sensitive and reliable, and the adjustment range is wide.

(4)The special shape of the air chamber improves the efficiency of powder selection.

(5)Reduce the differential pressure of the system.