HOME >> PRODUCT >> Main Equipment >> Drying Equipment

HOME >> PRODUCT >> Main Equipment >> Drying Equipment

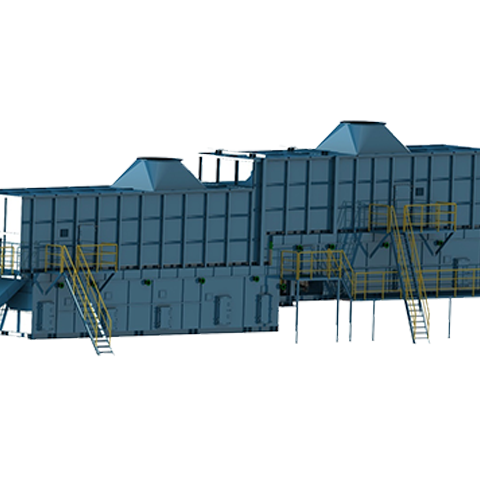

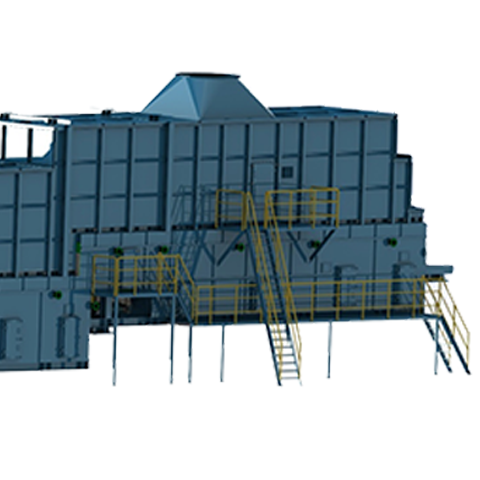

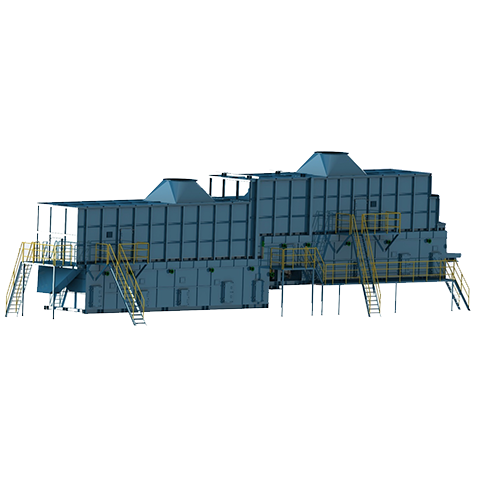

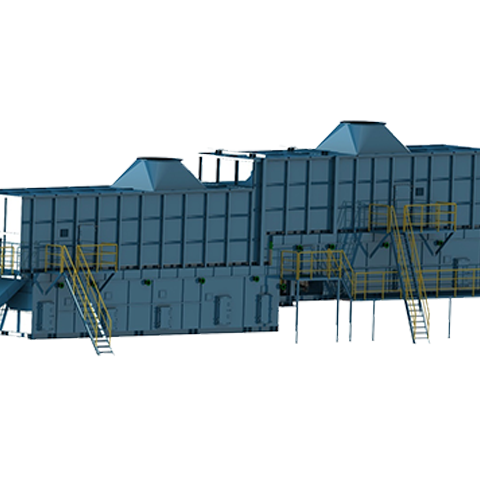

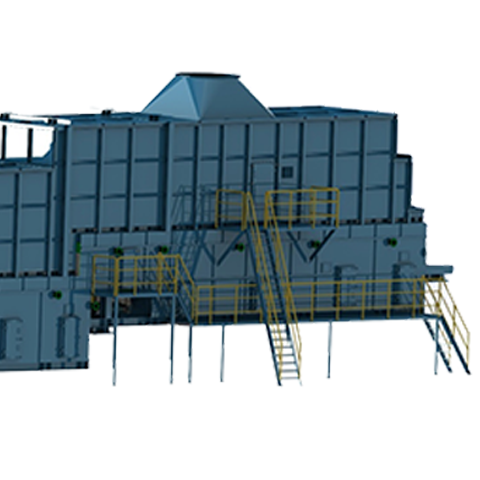

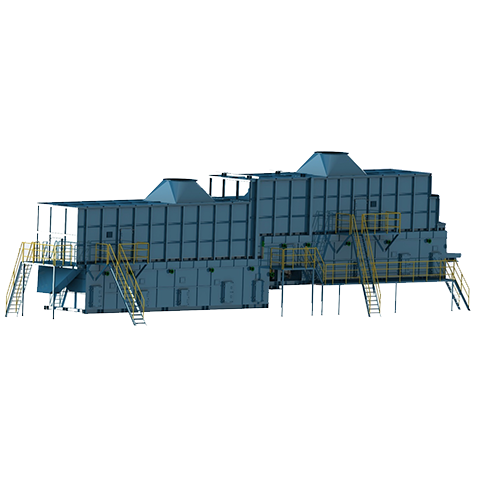

Fluidized Bed Dryer for Brown Coal

Introduction:

Brown coal/Lignite, also known as wood coal, is the lowest degree of coalification. A brownish black, dull and low grade coal intermediate between peat and bituminous coal. Strong chemical reactivity, easy to weather in the air, hard to store and transport, and serious air pollution when burning.But in our country, as the high-quality coal is almost mined out, brown coal has become the main coal used. As the degree of coalification of brown coal is too low, a large amount of black ash will float in the air when it is burned. Without coal washing and refining, the large use of inferior brown coal will lead to serious haze problem in our country. By using the induced draft fan,dry air passes through the dryer and forms a convection heat transfer with the heat source, in the negative pressure environment, the brown coal with higher moisture enters the dryer for mass and heat transfer exchange.The wet brown coal moves slowly in the dryer and is discharged after drying to complete the entire drying process. After drying, the brown coal can be used as fuel for power plants and cement plants, and can also be used as chemical raw materials, catalyst carriers, adsorbents for purifying sewage and recycling metals.

During many years of experiments,we have researched and developed fluidized bed dryer for brown coal, and applied for a number of national patents.

ZL 2021 2 2354591.0

ZL 2021 2 2347673.2

ZL 2021 2 2349622.3

ZL 2021 2 3009254.4

ZL 2021 2 2941935.8

(1)Heat exchange is sufficient to avoid the long-term exposure of brown coal to high temperature hot air and burning, which improves the production safety.

(2)Stable operation, low failure rate, reduce production costs.

(3)The moisture content of the finished products is in a relatively uniform state.

(4)Widely application, low moisture requirement for raw coal, easy control of moisture content and calorific value of the finished product.

(5)Easy maintenance.

(6)The drying capacity of a single equipment is large, up to 1.5 million tons per year.