Solid Waste Treatment

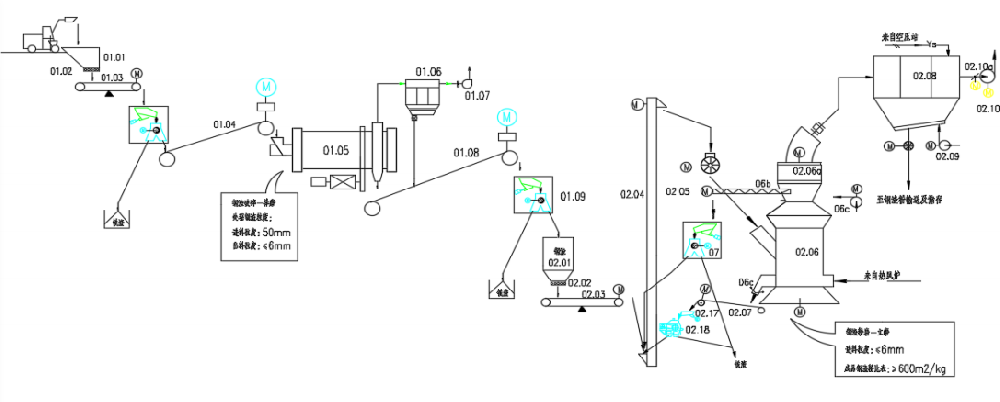

FIG. 1: Process flow of steel-slag powder

Jiangsu Xinlingyang can provide engineering solutions,including EPC,engineering design, main equipment supply,industrial automation, production operation and maintenance,technical services and so on for the annual output of 10 to 1 million tons of production lines of steel slag powder,blast furnace slag, phosphorus slag, lithium slag and other industrial solid waste grinding production line.

Main Advantages

(1)Strong adaptability for feeding material of steel slag, such as hot smoldering slag,hot splashing slag and roller steel slag.

(2)The fineness of steel slag powder can be stably controlled at the specific surface area ≥600㎡/kg

(3)Multiple iron removal process,ensure the full recovery of metal iron, steel slag powder metal iron residual ≤1.2%

(4)Special design for vertical roller mill, Reasonable configuration and selection, the power consumption of steel slag grinding system is 45~55kWh/t and ore slag grinding system is 32~40kWh/t.

(5)Patent technology for O-sepa powder separator, ensure Reasonable particle size distribution, Low Rotate Speed, Wide range for separation, Low resistance.

(6)Advanced DCS control system, high level of automation, high level of monitoring, user-friendly control

(7)The system layout is compact. Less occupation and low investment.